Diff - LSD clutch disks replaced.

Posted by Ferdinand

|

May 18, 2017 02:17PM

|

|

|

Registered: 15 years ago

Posts: 797 : Ottawa |

Well, that was a fun project...

My differential has had a lot of play in, backlash from throttle on/off, clack, clack. It sounded exactly like this guy's. [video]http://www.youtube.com/watch?v=EJu22zpAC34[/video] Recently I've noticed a much more alarming grinding noise when turning tight corners, just like this guy's at 0:15 as he turns tight right. [video]http://www.youtube.com/watch?v=2QuYLpDdtek[/video] That can't be good... It's the clutch disks in the Limited Slip unit. They're completely worn out. In a non-LSD diff the spider gears are mounted on shafts which are rigidly fixed. But the crossed shafts of the spider gears in a clutch-type limited-slip diff sit loose in angled notches between two separate halves of the diff cage. When torque is applied through the diff, the spider gear shafts force those two halves of the diff cage apart thereby applying pressure against the clutch disks. Because my clutch disks had worn so thin, there was excessive slack between those two halves, which meant the spider gear shafts had excessive slop causing that clacking noise on throttle on/off. The more alarming grinding noise means the friction surfaces of the clutch disks have worn down to bare metal. How hard can it be to fix something like that? Just replace the clutch disks, right? Well, the hardest part is actually getting the differential out of the car. Unbolt the driveshaft, and the two halfshafts, then there are four bolts holding the diff to the rear subframe, and one big bolt through the rubber hanger bushing at the rear. They're all awkward to reach. But, Eureka, I managed to get the dirty old diff disconnected, balanced on my floor jack, safely lowered to the ground and pulled out from under the car!

While I scrubbed the diff case clean of rust and grime in preparation to opening it up, the UPS truck arrived with my new clutch disks ordered from BimmerWorld.

Here's the case opened up and diff unit removed. It's a thing of beauty. The paddle blades are the pulse generators for the odo/speedo sensor.

LSD cover unbolted and lifted.

Here are all the various bits from inside the limited-slip unit. Click the photo to enlarge. There are a couple of important things to note, see red arrows pointing to "Shim". It is vitally important to remember which side, left or right, these parts were mounted on. These shim rings adjust the mesh between the pinion and ring gear. Also note the single tab on the outer perimeter of these pieces. They have to be at the top when fitted back into the diff housing. There is an oil hole next to that tab, which needs to be at the top. The arrows pointing at the "Notches" show the angled notch in which the spider gear shafts rest in each half of the spider gear cage. Drive torque works to spread the two halves apart increasing pressure on the clutch disks.

This is what the worn clutch disks looked like. Note they're not just worn thin, but they're also deeply scored. There was a corresponding build-up on the matching pressure plate. I just flipped those over so the pressure plates presented clean faces to the new clutch disks.

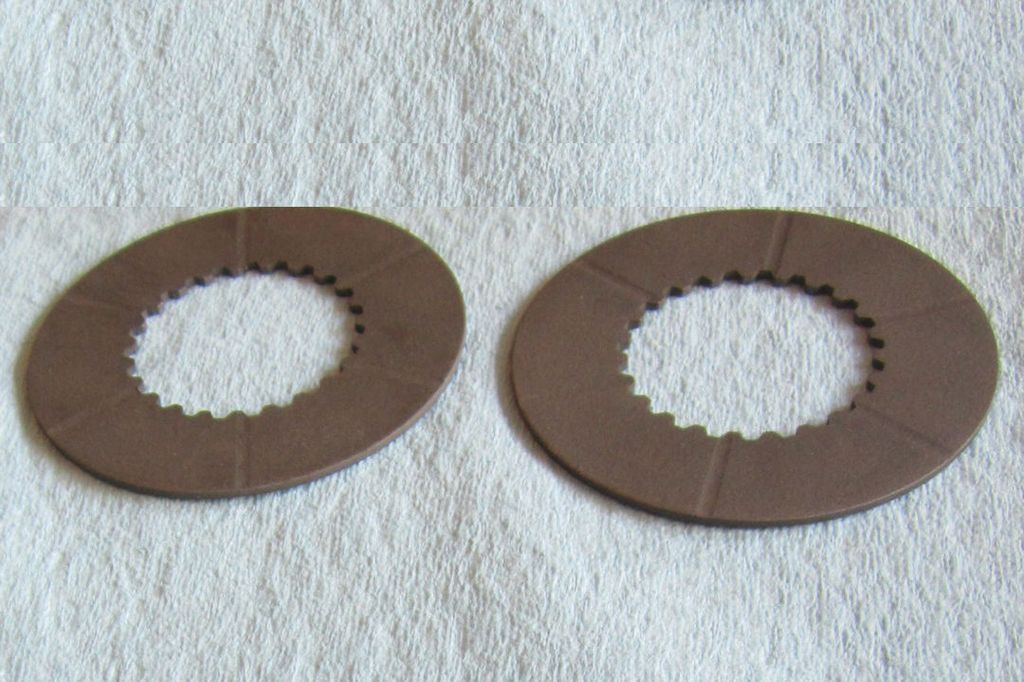

These are the brand new clutch disks.

Diff re-assembled and clean, filled with fresh oil, and ready to be re-installed.

There was some swearing involved in getting the diff re-installed. It's a pain getting the bolts lined up properly. The diff is HEAVY. I had it balanced on my hydraulic floor jack to raise it up. But I had to very careful it didn't fall off while I was jiggling it around to line up with the driveshaft bolts, and then fumbling with the four bolts that go in blind from the top through the subframe mounts. Big success, my car is happy again! |

|

May 20, 2017 10:03PM

|

|

|

Admin

Registered: 15 years ago

Posts: 944 : Lake Havasu City, Arizona |

Sorry, only registered users may post in this forum.